Resistance Furnaces

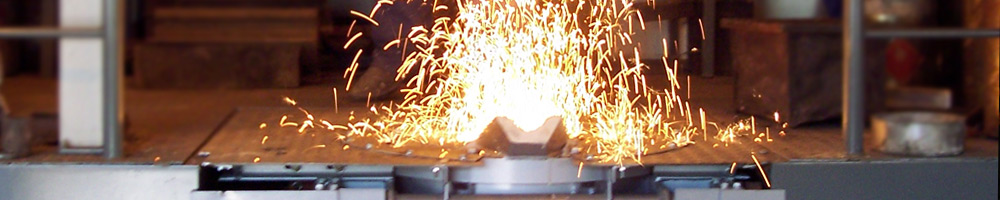

Odlévání z tavící pece ISTOL.

Induction Furnaces

Přidání legovacích přísad do tavící pece.

Salt Bath Furnaces

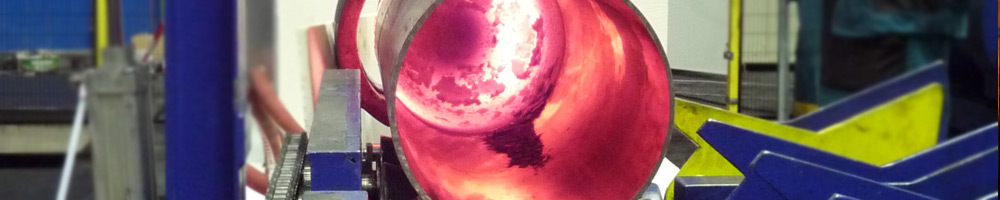

Ohřáté dno lahve.

HQ Quenching Power Supplies

Počátek ohřevu dna lahve.

is designed for drying shafts after grinding processing step and before preservation steps. The frame is welded from steel profiles and sheets. The furnace has three stages. Two heating stages and one cooling stage.

Heating is provided by electrical heating in the first two stages. The heat inside the furnace is distributed by two fans. That ensures equal temperature across the internal space. The third fan supports cooling to the requested output temperature. The temperature is measured by sensors. The internal lining is provided by fibrous insulation.

Input and output is covered by curtiens from a non-flammable material. The movement throught the furnace is provided by a conveyor belt from bent and tangled wire. The belt speed can be changed continuosly by a frequency convertor. A switchboard on the side of the furnace is equiped with protecting, switching and controlling units.

Electrical switchboard is on the surface ceiling. Controls are installed on both sides of the working area.

Service door for maintenance of th movement mechanism is in the furnace ceiling